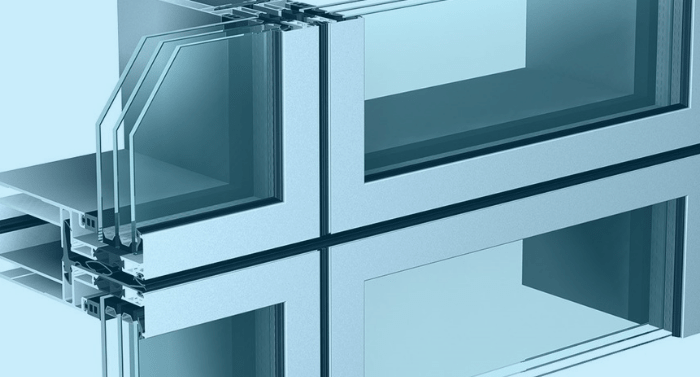

Semi Unitized Glazing

Semi-unitized glazing is a type of curtain wall system that combines elements of both stick-built and unitized glazing. It offers a balance between on-site customization and off-site fabrication efficiency. The key features of semi-unitized glazing are:

- The primary structural framing components, such as vertical mullions and horizontal members, are erected individually on-site in a grid pattern.

- The glass panels or spandrels (made of glass or aluminum) are pre-assembled and glazed in a shop or factory setting before being installed into the assembled grid framework on-site.

- The vertical mullions in most semi-unitized systems can span two floors, providing greater structural efficiency.

- The system is largely anchored to the face of the slab using embedded plates or inserts.

Advantages of semi-unitized glazing include:

- Allows for on-site customization to suit unique structural features while maintaining the efficiency of off-site fabrication.

- Reduces time and cost compared to fully stick-built systems, as the frames are pre-assembled off-site.

- Provides flexibility for building designers, allowing any combination of profiles, infills, external feature caps and glazing.